- All

- Product Name

- Product Keyword

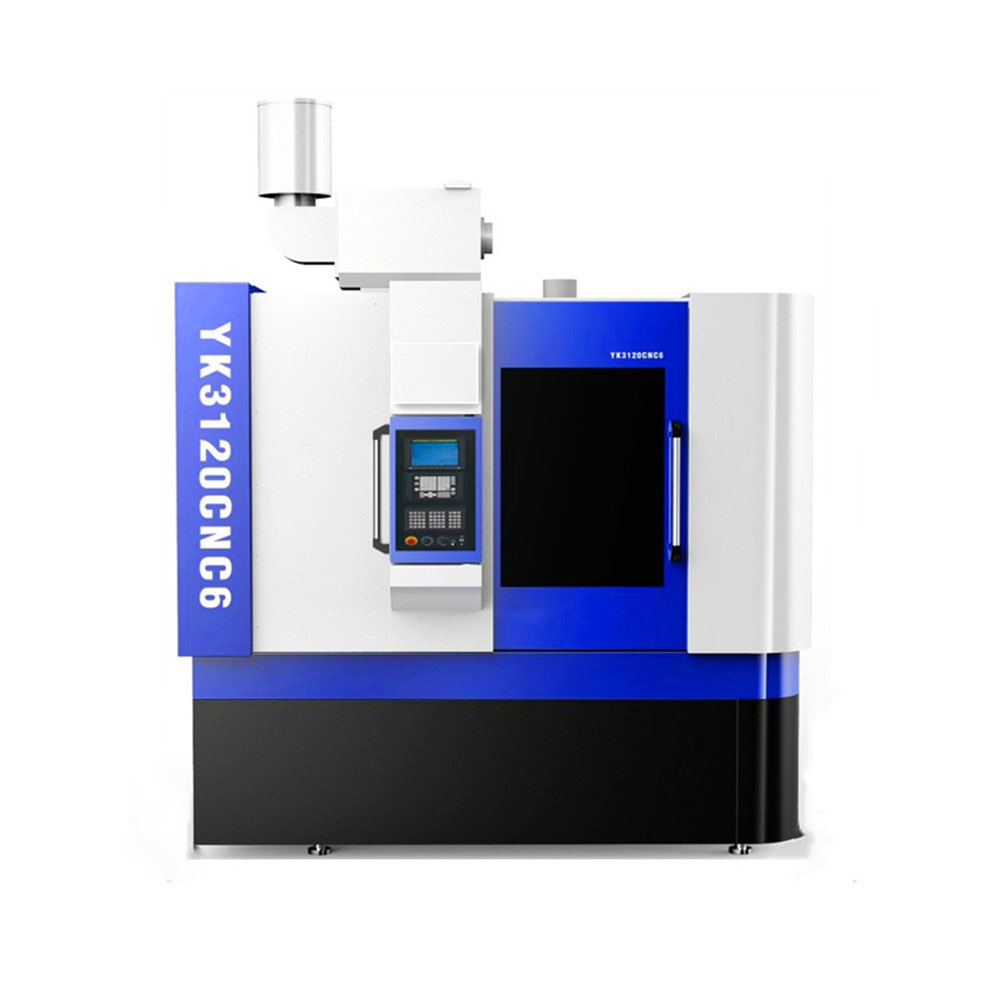

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-05-31 Origin: Site

In today’s manufacturing world, precision and efficiency are the backbones of any high-quality product. When it comes to gears, one machining process stands out for its ability to create high-precision components quickly and reliably: gear hobbing. Have you ever wondered how gears are made to the exacting standards needed for everything from automotive transmissions to heavy machinery?

In this ultimate guide, we’ll explore the world of gear hobbing machines. You’ll learn about the principles behind gear hobbing, the different types of machines, and the broad industrial applications they serve. By the end of this article, you’ll understand why gear hobbing machines are essential for manufacturers and how they help produce the gears that power modern machinery. Whether you're new to machining or an industry veteran, this guide will provide valuable insights into the gear production process.

Gear hobbing is a machining process used to create gears with teeth that interlock with other gears to transmit power. The process uses a specialized tool called a "hob" that cuts the teeth into a workpiece (known as a gear blank). Gear hobbing machines are designed to perform this task with extreme precision, using a combination of rotary and linear movements to cut the teeth efficiently.

A critical aspect of the gear hobbing machine is its ability to generate teeth profiles that meet tight tolerances. Whether it’s a simple spur gear or a more complex helical gear, hobbing allows for the efficient production of gears with high accuracy, ensuring they mesh perfectly with other components.

The process begins by mounting the gear blank on a spindle and attaching the hob to a separate rotating spindle. The hob’s teeth are designed to mesh with the gear blank’s surface, and as both rotate, the hob removes material to form the teeth. The number of teeth cut depends on the design and size of the gear. The gear hobbing machine continuously moves the hob along the blank’s surface, cutting the teeth incrementally until the gear is fully shaped.

For more complex gears, such as helical gears, the gear hobbing machine adjusts the hob’s angle to accommodate the teeth's spiral shape. This versatility makes gear hobbing an ideal method for producing a wide range of gears.

CNC gear hobbing machines are the most advanced type of gear hobbing machines available today. These machines are equipped with computer numerical control (CNC) systems, allowing for precise, automated gear cutting with minimal human intervention. CNC gear hobbing machines provide superior accuracy and consistency, making them perfect for mass production of gears with tight tolerances.

One key advantage of CNC gear hobbing machines is their ability to be programmed for different gear types and sizes. The machine can automatically adjust parameters like feed rate, cutting depth, and hob speed, allowing manufacturers to produce a variety of gears without retooling the machine.

Manual gear hobbing machines require more operator input and are generally slower than CNC machines. However, they are still widely used in smaller shops or for prototyping, where production runs are shorter, and flexibility is required. Manual machines are often preferred for custom gears or for low-volume production where the setup time for CNC machines would be too costly.

Despite their more labor-intensive operation, manual gear hobbing machines still offer precision and can produce high-quality gears when operated by skilled machinists. They are also less expensive than CNC machines, making them a good choice for certain applications.

Universal gear hobbing machines are versatile machines capable of performing both helical and spur gear hobbing. They are designed to handle a wide range of gear sizes and tooth profiles. These machines allow the operator to make adjustments for different gear types and are highly effective for industries that need to produce multiple types of gears in moderate quantities.

The flexibility of universal gear hobbing machines makes them popular in both small and medium-scale manufacturing environments. They are known for their durability and can be used for a variety of industries, from automotive to aerospace.

The automotive industry relies heavily on gear hobbing machines for the production of gears used in transmissions, axles, differentials, and other powertrain components. Gears in vehicles must be durable, precise, and capable of withstanding high stresses. Gear hobbing is the preferred method due to its speed and ability to produce gears that meet stringent performance standards.

In the automotive sector, gears must be produced with exceptional accuracy to ensure smooth operation and long-term durability. Gear hobbing machines are equipped to handle the large volumes required for mass production while maintaining high levels of precision.

In the aerospace industry, precision is critical. Gears used in aircraft engines, landing gear systems, and control mechanisms must meet the highest standards of performance and reliability. Gear hobbing machines used in aerospace applications are designed to produce gears that can withstand extreme temperatures, high pressures, and rigorous operational conditions.

The demand for lightweight yet durable gears in aerospace applications makes gear hobbing an ideal process, as it can create gears with the required strength and surface finish for mission-critical components.

Heavy-duty machinery such as conveyors, mills, and excavators rely on gears to transfer power and ensure efficient operation. Gear hobbing machines are crucial in the production of gears that drive these machines, as the gears need to be both strong and precise to perform effectively under heavy loads.

Gears for industrial machinery are often subject to extreme wear and tear, making it essential that the gears are produced using high-quality methods like gear hobbing. The ability to create gears with high strength and minimal friction ensures that these machines continue to operate smoothly in demanding environments.

Robotics and automated systems also require highly precise gears to ensure smooth and accurate movement. Whether it’s for a robot’s arm, a conveyor belt, or automated assembly lines, gear hobbing machines are used to produce gears that provide the necessary power transmission and motion control.

As automation becomes more widespread, the need for high-precision gears increases. Gear hobbing ensures that these components are made to exact specifications, allowing robots and automated systems to perform with high efficiency and precision.

One of the key benefits of gear hobbing machines is their ability to produce gears with exceptional precision. The ability to cut gears with tight tolerances ensures that they operate smoothly and efficiently in their applications, whether in automotive, aerospace, or industrial machinery. This precision minimizes wear, reduces noise, and increases the lifespan of the gears.

Gear hobbing machines are designed for fast, continuous gear cutting, making them ideal for mass production. These machines can produce gears quickly while maintaining high-quality standards, making them a cost-effective choice for manufacturers who need to produce large quantities of gears within a short time frame.

Modern gear hobbing machines are highly versatile, capable of producing a wide range of gear types, from simple spur gears to more complex helical and bevel gears. This versatility allows manufacturers to meet the diverse needs of various industries, making gear hobbing machines indispensable in the production of gears for different applications.

Once set up correctly, gear hobbing machines can produce gears consistently over long production runs. This consistency is crucial for maintaining quality and performance in mass production environments. Whether you're making a single prototype or thousands of gears, gear hobbing machines ensure that every gear meets the same high standards.

In conclusion, gear hobbing machines play a critical role in producing high-quality gears that are essential for a wide range of industries. Whether in the automotive, aerospace, industrial machinery, or robotics sectors, these machines provide the precision, efficiency, and reliability required for modern manufacturing. By understanding the different types of gear hobbing machines and their applications, you can make more informed decisions about the best tools for your production needs.

At GEEPRO, we offer state-of-the-art gear hobbing machines designed to meet the demands of various industries. Our machines are built for precision, durability, and versatility, ensuring that you get the best results every time. Choose GEEPRO for all your gear machining needs and elevate your production capabilities.

A: Gear hobbing machines are used to efficiently cut gear teeth with high precision. Compared to processes like gear shaping or milling, hobbing is faster and more suitable for mass production, especially for gears with simpler profiles like spur and helical gears.

A: Gear hobbing uses a cutting tool called a hob that precisely shapes the gear teeth as it rotates. The machine’s ability to maintain tight tolerances ensures that the gears fit perfectly with other components and operate smoothly.

A: Gear hobbing machines are used to produce a wide variety of gears, including spur gears, helical gears, bevel gears, worm gears, and more. Each type requires different cutting parameters, which gear hobbing machines can easily accommodate.

Copyright © 2023 Wuxi Geepro Gear Technology Co.,Ltd. All rights reserved. Sitemap Support by leadong.com Privacy Policy