- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

Product Description

Improve productivity: Reduce the number of workpiece clamping times

Enhanced machining accuracy: machining of internal and external round surfaces can be accomplished with greater consistency and precision, ensuring the quality of the part.

High flexibility: for a wide range of workpieces of different shapes and sizes, whether small-diameter precision parts or large-diameter heavy components, all can be handled efficiently.

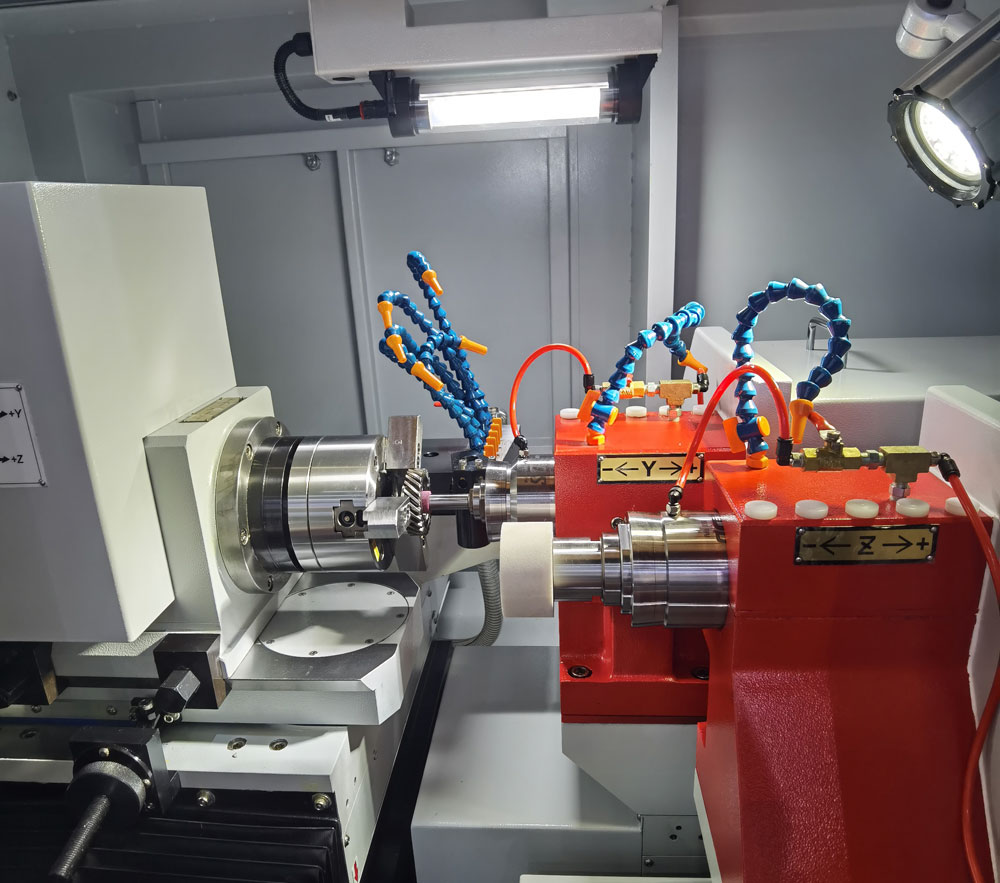

The machine tool is comprised of a 3-axis (X feed axis, Z1 grinding wheel axis, Z2 grinding wheel axis) with a 2-linkage CNC compound grinding machine. Once Clamping, it can complete internal, external, end face, and rough grinding of the cycle.

The 3-axis CNC system supports programming automation and can preset complex machining paths and parameters, with optional automatic loading and unloading to realize unattended continuous machining, which improves productivity and consistency of batch processing.

Our advantage is that the grinding cycle is automated (with a automatic feed, withdrawal, and rough grinding components); the machine is also equipped with a high-precision grinding wheel and a high-precision ball, which ensures an excellent degree of accuracy and a smooth surface.

ID grinding scope: 20-200mm

Max. Grinding depth: 200mm

Max. Grinding OD scope: 30-300mm

Max. Grinding length: 200mm

Copyright © 2023 Wuxi Geepro Gear Technology Co.,Ltd. All rights reserved. Sitemap Support by leadong.com Privacy Policy