- All

- Product Name

- Product Keyword

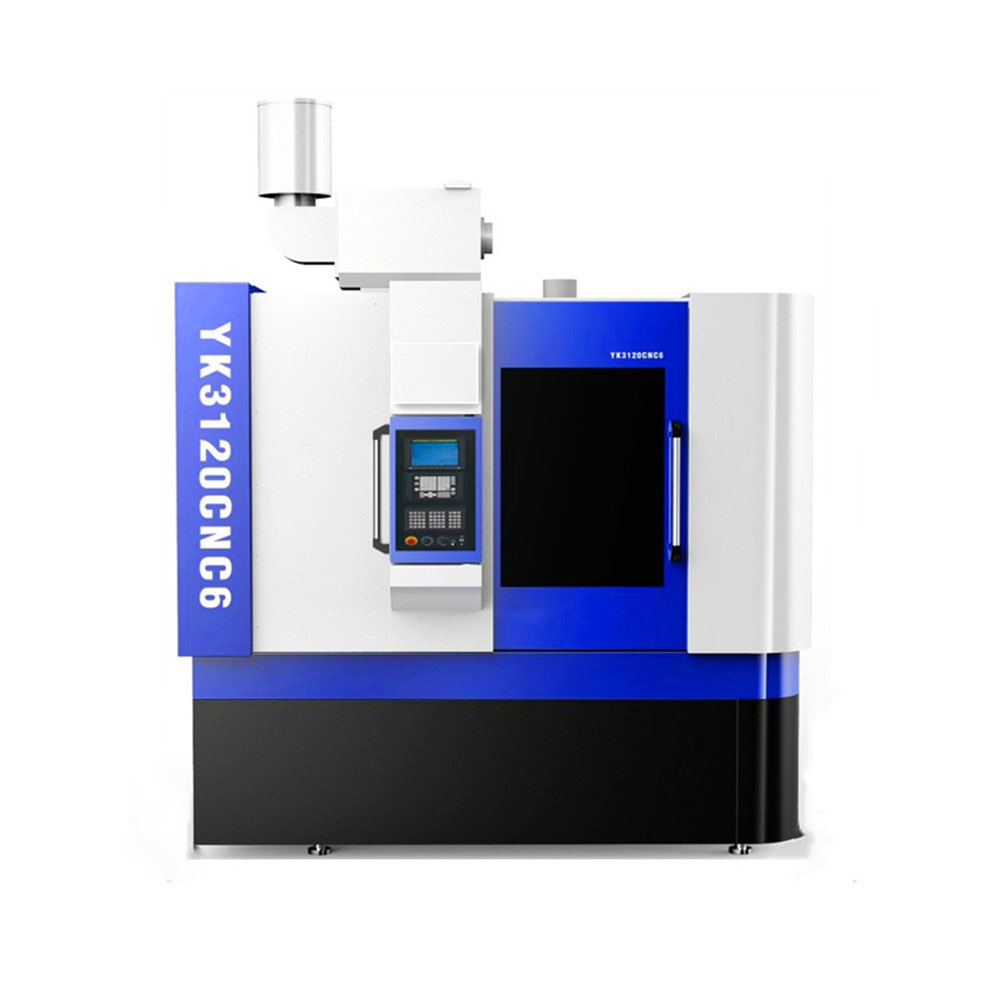

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Dual Work Spindle Technology for High-Volume Gear ProductionGear grinding is a crucial process in manufacturing, ensuring precise gear finishes for optimal performance. High-volume production faces challenges like bottlenecks and delays. In this post, you'll learn how the 5 Module Horizontal CNC Wor

Maximizing Uptime on 280mm Capacity Hobbing MachinesIs your gear manufacturing process running at peak efficiency? Downtime can be costly. Discover how a Gear Hobbing Machine with Automatic Loading And Unloading System can transform your operations. Maintaining uptime is crucial for productivity and

Ultra-Precision Surface Grinding: CNC PLC Double Column TechnologyImagine achieving precision so fine it seems impossible. CNC PLC Double Column Surface Grinding Machines make this a reality. These machines combine cutting-edge technology with robust design, providing unmatched accuracy for super-hi

Precision in Large Gear Manufacturing: The Role of CNC Vertical Gear Cutting MachinesPrecision is crucial in gear manufacturing. Large gears face unique challenges. CNC Vertical Gear Cutting Machines offer solutions. In this post, we'll explore their importance and benefits.Understanding CNC Vertica

Ever wondered how gears are precisely crafted for heavy-duty applications? These machines ensure accuracy and efficiency in manufacturing. In this post, you'll learn about the importance of gear cutting in heavy-duty production and discover the capabilities of the 12 module capacity CNC vertical gea

We are delighted to announce the successful acceptance of the G200 CNC Vertical Gear Hobbing Machine at our customer's site in Belgium!

With the continuous advancement of intelligent manufacturing, the traditional machining industry is undergoing a profound transformation.

Technical Highlights of the G400 Gear Hobbing MachineIn today's advanced manufacturing landscape, ongoing developments in gear production technology are continuously driving the evolution of automation and high-precision equipment.

Automated Gear Skiving Machine: Efficient and Precise Internal and External Gear Turning SolutionWith the continuous advancement of manufacturing intelligence, gear processing equipment is rapidly evolving towards automation, digitalization, and precision.

Compact CNC Gear Cutting Machine: Ideal for StartupsIn the industrial manufacturing sector, gears are critical components in numerous mechanical systems, with widespread applications across automotive, aerospace, and machinery industries.

IntroductionWhen it comes to manufacturing precision gears, ensuring that the equipment used is properly maintained is critical. The Gear Shaping Machine plays a vital role in this process, offering high efficiency and precision for cutting gears of various sizes.

IntroductionWhen it comes to precision engineering and manufacturing, selecting the right equipment is crucial. The Gear Shaping Machine is one of the most essential tools for gear manufacturing. However, with so many options available, how do you ensure you are making the right choice?

IntroductionAre you looking to improve the precision and efficiency of your small-batch gear production? Gear shaping machines are the unsung heroes of the manufacturing world, offering a host of benefits that can streamline your production processes and enhance the quality of your products.

IntroductionGear shaping machines are essential for the manufacturing of gears used in a wide variety of industrial applications, from automotive to aerospace. These machines are designed to precisely shape gears, ensuring they meet specific requirements for strength, precision, and durability.

IntroductionGear shaping machines have become a crucial component in manufacturing processes that involve precision gear cutting. But why are they so important? With the ever-evolving technology in machinery, gear shaping machines have evolved to provide superior accuracy, speed, and versatility.

In today’s manufacturing world, precision and efficiency are the backbones of any high-quality product. When it comes to gears, one machining process stands out for its ability to create high-precision components quickly and reliably: gear hobbing. Have you ever wondered how gears are made to the exacting standards needed for everything from automotive transmissions to heavy machinery?

Have you ever wondered how gears are made with such precision? Gears are fundamental components in many industries, from automotive to aerospace, and their quality is vital for the performance of machines. Whether it's a gear used in a car transmission or a turbine in an aircraft engine, the manufacturing process behind them is complex and demands precision. One of the most reliable methods for producing gears is through gear hobbing machines.

In the world of precision manufacturing, choosing the right gear hobbing machine can make all the difference. Whether you're in the automotive, aerospace, or industrial machinery sector, the gears you produce must meet stringent quality standards, and the machine you use is crucial for ensuring those standards are met. Have you ever wondered what makes one gear hobbing machine stand out from another? The truth lies in understanding the key factors that influence their performance, reliability, and efficiency.

When it comes to manufacturing gears with exceptional precision, speed, and reliability, gear hobbing machines stand at the forefront of technology. If you’ve ever wondered how gears in everything from cars to industrial machines are made with such high precision, the answer often lies in the gear hobbing machine. This versatile and efficient machine has become essential in many industries, offering advantages that improve both production efficiency and product quality.

In the world of precision manufacturing, gear hobbing machines play a pivotal role in producing high-precision gears used across various industries, from automotive to aerospace. But like any piece of machinery, gear hobbing machines require proper maintenance to continue performing at their best. Without routine care, these machines can experience wear and tear, leading to costly downtime, reduced efficiency, and compromised gear quality.